IC Programming

1、Offline burning advantages:

Simplify the production process, save time and cost to import, and increase production capacity.

2、Pulimings advantages:

* Focus on IC burning industry for 20 years

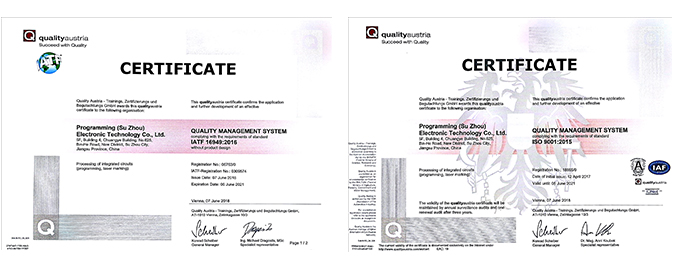

* ISO9001:2015 and IATF 16949 double certification

* Professional teams in the burning industry for an average of more than 5 years

* ESD grounding and equipment grounding dual system

* Complete each process in accordance with the quality management system

*Temperature constant humidity, 100,000 level purification workshop

* Shared resources across sites to respond quickly to needs

*Fully automated burning and AOI detection

3、Type of burning IC:

UFS、MCU、eMMC、NAND FLASH、S-FLASH、EEPROM、FPGA.......

packaging:WLCSP、QFP、QFN、BGA、TSOP、SOIC、SOT等。

4、Price factors:

The unit price of the IC body-the ease of IC support-the product requirements for using this IC(especially relationship security)-IC capacity-IC burning time-the cost of burning equipment-the amount of orders from customers.

5.Production control priorities:

* F/W Management: Authorized management, dedicated F/W server

* Customer Materials Tracking: Using MES system, material information can be tracked based on work order information

* Material wet sensitive level control: record the unpacking time and packing time of each package or volume of material;

* Control of burning programs: ERP and MES dual system management to ensure the correctness of F/W calls

* Quality control: first inspection; Inspections; 200 % appearance inspection; AOI appearance inspection; Final inspection; MES System Control Label Printing

* Adverse handling: Do business according to customers request

CH

CH